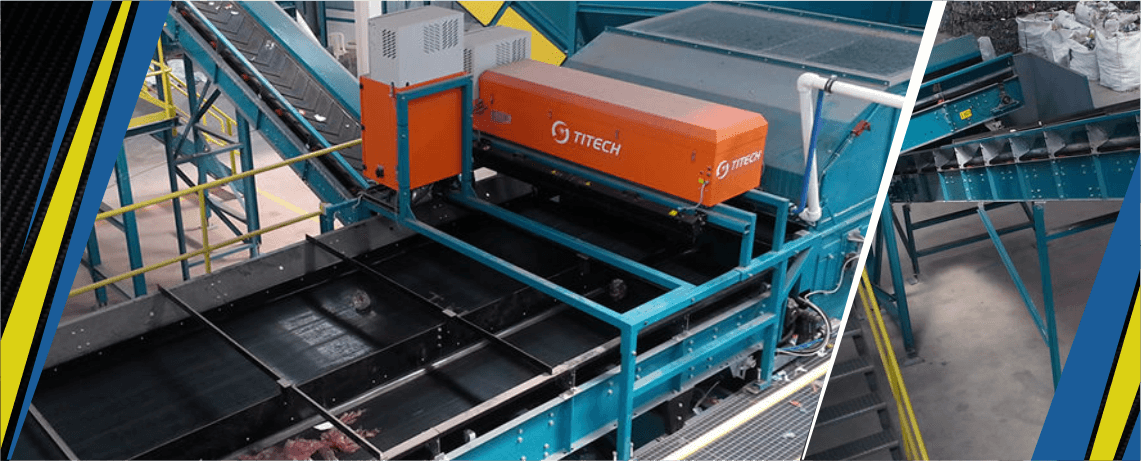

MIXED PLASTICS SORTING PLANTS

Mixed plastics sorting lines are the facilities that enable the automatic separation of materials such as HDPE, PP, PS, PVC, PC, taken from the market or coming from a household / packaging waste sorting plant and separating them with high precision according to their color and material type. These facilities vary, depending on the material composition, but are basically equipped with a bale opener (if the material comes baled), a pre-sorting platform, ballistic separator, magnet, eddy-current, optical separators and quality control platforms. Here, design is made by evaluating the placement, number and combination of optical separators according to the input morphology and desired output amount. In mixed plastic separation, the recognition of the material requires skilled workmanship. For this reason, it is a great advantage to have these automatic facilities. It is possible to reach higher quality and higher capacities with less skilled personnel. Capacities reach 6-7 tones per hour. The separated materials are mainly White HDPE, Color HDPE, White PP, Color PP, Transparent PET, Color PET, PC, PS and so on. However, as the system is open to update and programming, it is possible to change the program in many different types of plastics.