NYLON FILM SORTING PLANTS

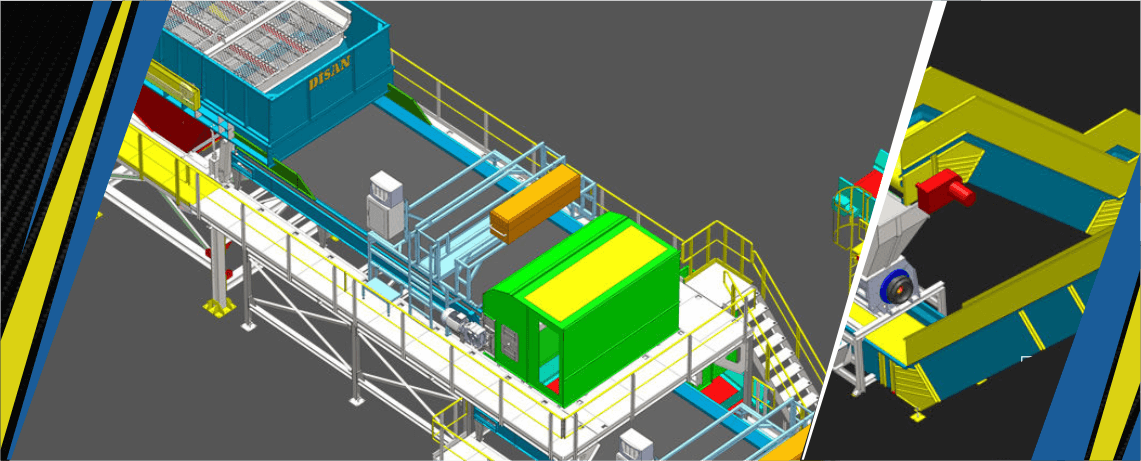

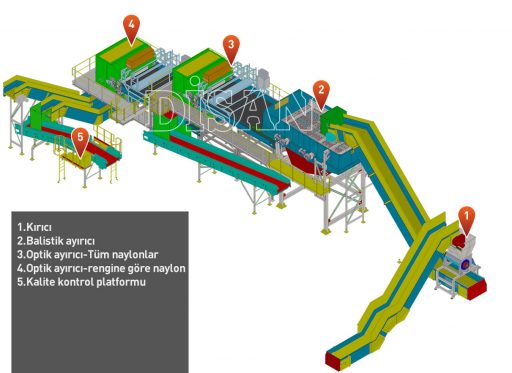

Automatic Nylon Film sorting plant is designed to reduce the labor costs and increase the quality level of LDPE film recycling companies. Moreover, thanks to the separation efficiency of the plant, it provides a great advantage even in raw material purchases and reduces costs. Basically, a shredder makes the materials smaller than 300 mm and seperates the adherent material from each other, allowing the processing to be carried out in a later stage, and the shredded material is conveyed to the ballistic separator by a dosing conveyor. The ballistic separator provides the elimination of waste such as dust and soil in the material and ensures the distribution of the material for the next stage.

Homogeneous material distribution is very important for proper separation in these plants. The material fed from the ballistic separator to the optical separator is sorted by means of the optical separator.

Generally, in the first optical separator, non-LDPE material is blown off and taken out of the system. The remaining material is fed into a second optical separator, depending on the material input composition, divided into two parts by blowing, as transparent LDPE and colored LDPE.

However, in this last part, different designs can be made according to the needs of the following recycling plant by making various variations according to the needs.

LDPE film is a very difficult material to be sorted by hand, the average staff can sort about 30 kg film in one hour. Therefore, in order to reach high tonnages, there is a serious need for personnel and they have to know the material. However, in the automated plant, it is possible to reach high capacities and high quality levels with low personnel numbers.